Consumers prefer buying online, with global e-commerce increasing by 18% just last year. However, the delight of seeing another box sitting on your doorstep tends to overwhelm the uncomfortable reality that e-commerce generates hundreds of tons of packing trash.

Fast Company estimates that 165 billion parcels are sent in the United States each year, equal to more than 1 billion trees! The fact is that as internet shopping expands, so will our environmental effect unless we drastically modify our shipping practices.

The Customer Experience Doesn’t End Once the Purchase Is Made

The influence of eCommerce, which has fueled a fundamental shift in how customers engage with and purchase from your organization, is not restricted to the online experience. With online sales, e-commerce packaging is more crucial than ever, providing your brand as a consumer’s first physical touchpoint. Shipping, unpacking, and packaging disposal are all important phases in the eCommerce buyer’s journey, so make sure your packaging is up to the chore. Your brand’s reputation is on the line if it doesn’t.

How are online businesses responding?

An inefficient or irritating packaging experience may harm a customer’s opinion, and eCommerce businesses are well aware of this. There is just too much variety in the marketplace for firms to not compete on offering a good experience. Online customers are knowledgeable, and quality plays a significant factor in their happiness.

What is Frustration-Free Packaging?

Frustration-free packaging (FFP) refers to the use of effective, easy-to-open solutions made of recyclable materials to optimize product packaging for the eCommerce environment. On numerous levels, this effort helps both the consumer and the producer.

Traditional packaging should only be used if you want your clients to be more interested in the package than the product. When we speak of frustration-free packaging, we are referring to both customers and producers. It is simple to unpack for customers. FFP is the minimum turnaround time (TAT) for packaging for manufacturers. The video below shows how time-consuming unpacking a “not-so-smartly” packed product may be. There’s also the cost of packing materials. You can use frustration-free packaging strategies to make your packing easier. We’ll explain why.

10 Benefits of Frustration-Free Packaging for Buyers & Sellers

1. The Correct Box Sizes

If you pack your product in a large or tiny packaging box, it is more likely to be damaged during delivery. The appropriate box size reduces the amount of material and time required to pack orders. As a result, more products may be shipped at once.

You might take the following steps to minimize the box size while maintaining product safety.

• Use bubble wraps or polystyrene foams for added protection

• Custom boxes with logo can be used for packaging in scale.

2. There’s No Need for An Extra Shipping Box

Except for delightful gifts, no one enjoys a box inside a box, followed by the real object. As a result, many e-commerce merchants are working with manufacturers to develop packaging that does not require shipment in a container. DELL, for example, is using this strategy even for delivering sensitive electronics.

3. Still Winning Despite Reducing Material, Assembly, and Shipping Costs

When you start by lowering the package size, you’ll gradually minimize the amount of material needed, as well as the cost of assembly and shipment.

Material: The exterior packaging material, fillers, and tapes may all be saved using FFP. It lowers the cost of packing materials, especially in large-scale packaging.

Assembly – The smaller the box, the less work, and logistics are required.

Shipping: When calculating the cost of shipping, the product’s dimensional weight is taken into account. To calculate the shipping cost, the dimensional weight approach takes into consideration both the package’s weight and volume. Compact packaging has a smaller volume and hence a lower-dimensional weight.

4. It’s Straightforward to Open Frustration-Free Packaging

Have you ever wondered why e-commerce has become so popular in such a short period of time? It is due to the fact that it is easily accessible. Frustration-free retail packaging is based on the same concept: making it easy and comfortable for customers to unpack their purchases. The package is simple to open yet also maintains product safety while in transportation. During delivery, you will not be confronted with a product spill or an open box.

• The packaging eliminates blister packs, which is one of the most critical aspects of easy-to-open packaging.

• The sealed clamshell is not recommended since it contains less or no filler materials such as packing peanuts, shredded papers, and so forth.

• Wire ties are not used unless essential (for example, while packaging headphones, data cables, or pieces of assembling toys).

5. Both packing and unpacking time is saved

The proper form of the box for packing is favored by the frustration-free packaging. The rectangular box with square corners is the ideal form. It makes stacking the packages a breeze. Furthermore, the box’s basic form does not need skilled packing. Assembling the components is quick and straightforward. The boxes can be stacked and moved along the production line due to their simplified form. In a large production, this saves a lot of packing time. In addition, FFP makes use of fewer gums and tapes. It makes it easier for customers and merchants to open the box.

6. Packaging that isn’t a hassle to use makes the supply chain run smoothly

If your company manages the supply chain, the hassle-free packaging can benefit in the following ways:

• The smaller package size allows you to mail more products at once.

• The box with no cuts is easier to handle, and the ideal rectangular form of the packaging provides a firmer basis for support during shipment. This packaging is easy to stack and guarantees uniform weight distribution.

7. In terms of packaging fillers, there is less waste

Because the packing is less frustrating, it uses less package material, which saves money. Packing peanuts, air cushions, shredded and crumpled papers are all joint fillers in packaging. Despite the fact that these fillers are reusable, customers rarely utilize them.

Blister packs and wire ties are also used in conventional packing to keep the pieces organized. However, this technique necessitates a variety of packing materials. Even if these materials are recyclable, sorting them incurs a cost.

8. Furthermore, most of the Frustration-Free Packaging is recyclable

That is correct. FFP prefers packaging materials that are either recyclable or recyclable.

9. Packaging that isn’t a hassle to use is more environmentally friendly

Yes, the frustration-free packaging remains that way during its entire lifespan. It assures the least amount of environmental effect possible. Here’s how to do it:

1. Compact packaging: The FFP demands compact packaging or box packaging that is the correct size. It reduces the amount of packing material used and the carbon footprint connected with the production of these goods. LEGO, for example, has been able to cut its package size by 14%.

2. Material diversity is limited: FFP does not offer a selection of 10 distinct packaging materials. However, it makes separating packaging trash for recycling much more accessible.

3. Avoiding package inserts: Despite the fact that packaging fillers are reusable, few individuals do so. As a result, FFP uses the least number of fillers possible, resulting in less packing waste.

10. Is FFP Able to Adhere to the Basic Packaging Requirements?

Simple packaging is required. It will be straightforward to pack and unpack a product if it is packaged in a basic container. So, let’s start with the fundamental packaging needs.

• Sturdy: The packing must be able to withstand the turbulence of shipment and storage.

• Product safety: Packaging should have no interaction with the items. The contents of the packing container (custom corrugated cardboard boxes, mailers, polyethylene packages, and so on) must be protected from both internal and external harm. The packing must also be spill-proof in order to avoid causing harm to the other items during transportation.

• Cost-effective: Not all manufacturers can afford to spend thousands of dollars on the packaging. Even low-cost packaging should assure product safety and durability.

• Simple to handle and open: As a general rule, the recipient should be able to unpack without the assistance of others or the use of heavy tools. Also essential is the ease with which the package may be handled from the production to the consumer.

• Labeling: One of the most crucial aspects of packing is labelling. A printed surface or the ability to affix labels should be included in the package. Important information on the label contains product instructions, delivery address, recyclability, and expiration dates, among other things.

Is it possible for frustration-free packaging to meet these fundamental packaging requirements? Yes, it is correct. The FFP is a packaging method that is both simple and practical.

What is the best packaging material for a hassle-free package?

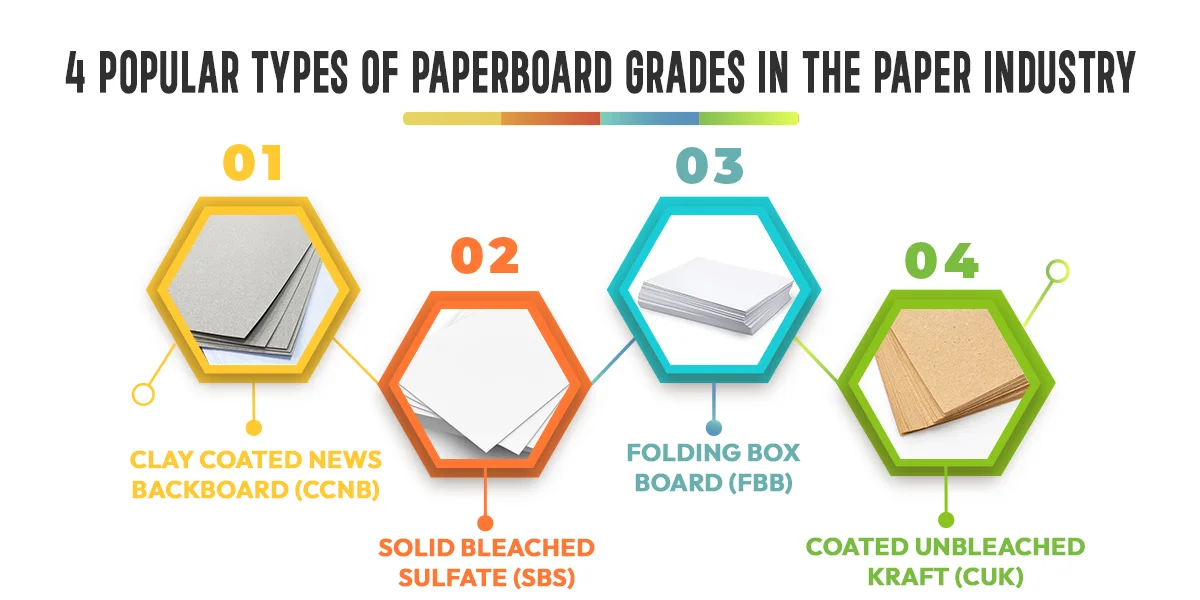

The FFP prefers packaging that uses a limited number of materials. A package including cardboard, blisters, wire ties, bubble wrap, and tapes in one unit, for example, cannot be termed a frustration-free package. There are no specific guidelines for the usage of packaging materials. Blister packaging, for example, may be made from both recycled and virgin polymers. By employing minimal materials and a basic design, packaging may become less aggravating. The following are some of the ideal packing materials for FFP:

• Kraft paper (e.g., corrugated or chipboard)

• Polymers such as PET, HDPE, LDPE, and PP

• Other recyclable and biodegradable materials

You would think that the advantages of frustration-free packaging boil down to fewer human efforts, less packaging material, lower costs, and, eventually, less environmental effect. However, it is, in reality, a matter of need. With millions of tons of packaging trash ending up in landfills each year, every move toward a long-term solution is worthwhile. It all starts with the need to minimize packaging material, which leads to lower package logistics, shipping, recycling, and trash disposal costs and a lower total carbon footprint. So, yes, the hassle-free packing is also cost-effective.

Some distinctions between frustration-free packaging and ordinary packaging

One of the trends that will define the future of packaging is frustration-free packaging.

The following are some of the most significant deviations from normal packaging:

• Packaging that is more environmentally friendly. The goal of the Frustration-Free packaging guidelines is to reduce the amount of packing used. Considering the Silver Edge packaging material, the usage of plastic packaging is likewise limited.

In this way, we encourage salespeople and distributors who work via our sales channel to create environmentally friendly packaging.

It isn’t the first time Amazon has campaigned for environmentally friendly packaging. In 2017, the firm claimed to have reduced packaging materials used by 215,000 tons, eliminating the usage of 360 million shipping boxes.

• Packaging that is certified and optimized. We provide a set of tests and standards to encourage firms to optimize their packaging using its frustration-free packaging.

Distributors and salespeople will have access to important information about their packaging through a series of tests and will be able to enhance its design to save needless expenses. At the same time, these tests ensure that the product reaches the ultimate consumer in a healthy and safe state.

• A package that is simpler to open. Many merchants used to use conventional packaging, such as plastic, which was more physically attractive but made the opening procedure more difficult for the end customer.

Read our previous blog from here and know more about Silver Edge Packaging.