Corrugated packaging is a necessity for various industries to keep their products organized and safe from damage. A wide range of corrugated cardboard materials with various thicknesses is used to manufacture protective packaging for products.

From 1871 to the present day, corrugated materials have multiple uses and functionalities. With their wave-like dimensions and durability, corrugated packaging materials are excellent for retail and shipping packaging.

Let’s learn in depth about the types, comparison, and the benefits of corrugated cardboard flutes.

What is Corrugated Flute?

In corrugated materials, the flute is a wave-like layer with various thicknesses. With their durability, stackability, and rigidity, corrugated cardboard materials are used to manufacture shipping boxes and mailer boxes.

The distance between each flute ensures the durability and stackability of the flutes, as A flute corrugated stock is available with a thickness of about 5 millimeters or 14 inches, and F flute stock comes with 0.8 millimeters or 1/32 inch thickness.

Different Corrugated Flute Types

Corrugated cardboard flutes are available in 5 different types to manufacture protective packaging for both small and bulky products.

- A Flute Corrugated

- B Flute Corrugated

- C Flute Corrugated

- E Flute Corrugated

- F Flute Corrugated

Apart from the above flutes corrugated flutes are also available in other forms, such as:

- BC Flute

- EB Flute

- EC Flute

- FE Flute

Let’s discuss them in detail!

A Flute

A flute is considered the thickest flute. Its thickness ranges from 5 millimeters or 14 inches. A flute in a single layer of corrugated cardboard has 36 flutes.

Because it is thicker and more durable, this A flute is quite effective for manufacturing packaging for delicate and bulky items, including jars, electronics, and other fragile items.

B Flute

B flutes, due to their thickness, puncher-resistant nature, and durability, are very useful in manufacturing protective corrugated boxes. This stock is available in 2.5-3.5 mm thickness. This stock is also quite suitable for printing and is more affordable than E flute.

These packaging materials are effective for manufacturing mailer boxes, shipping boxes, and other durable packaging for various products.

C Flute

With a 3.6 to 4.2 mm thickness, C flute provides more durability and is used to manufacture packaging for fragile small products. Because of their excellent stackability, these materials are effective for packing delicate home decor items and other retail items. C flute corrugated thickness is also ideal for the production of inserts for packaging.

E Flute

E-flutes have high printing capacity and are commonly used to manufacture premium-quality cardboard packaging, such as custom printed cosmetic boxes and packaging for electronics and perfumes. Apart from this, because of their lightweight and food-grade nature, these cardboard flutes are perfect for manufacturing takeout boxes for various food items.

E flute single wall recommended for various industries:

- Bakeries

- Restaurants

- Food Brands

- E-commerce Brands

F Flute

With 0.8 mm thickness, F flutes are the thinnest corrugated flute. Accordingly, a linear foot of corrugated cardboard in F flute contains near about 128 flutes. These materials are also effective for full color printing and are mostly used to manufacture lightweight yet durable packaging for small retail items to keep them safe during display and shipping.

After learning about the different types of corrugated flutes, let’s discuss their various combinations to create a thicker yet safer packaging for delicate items.

Various Combinations of Corrugated Flutes

With the combination of various types of cardboard flues, the packaging industry manufactures protective packaging for fragile items to meet all their packaging needs. The combination of flutes provides the double cushioning to products.

BC Flutes

The combination of the B flute and C flute corrugated cardboard makes the BC flute (7mm-8mm). This flute profile is also known as double cushion, meaning double protection for products. Therefore, these corrugated board flute types are used to manufacture safer and secure packaging for products. These flutes provide full protection to products from punchers, external pressure, and other physical damage.

EB Flutes

EB flutes are the combination of both E and B flutes with a 4.5mm to 5mm thickness. These materials are stronger than the B flute because of their two walls. If you want to improve the safety of your products, you should choose EB fluted corrugated cardboard packaging materials. This micro flute corrugated is excellent for both printing and the protection of products.

Other Factors to Consider While Selecting Corrugated Stock for Product Packaging

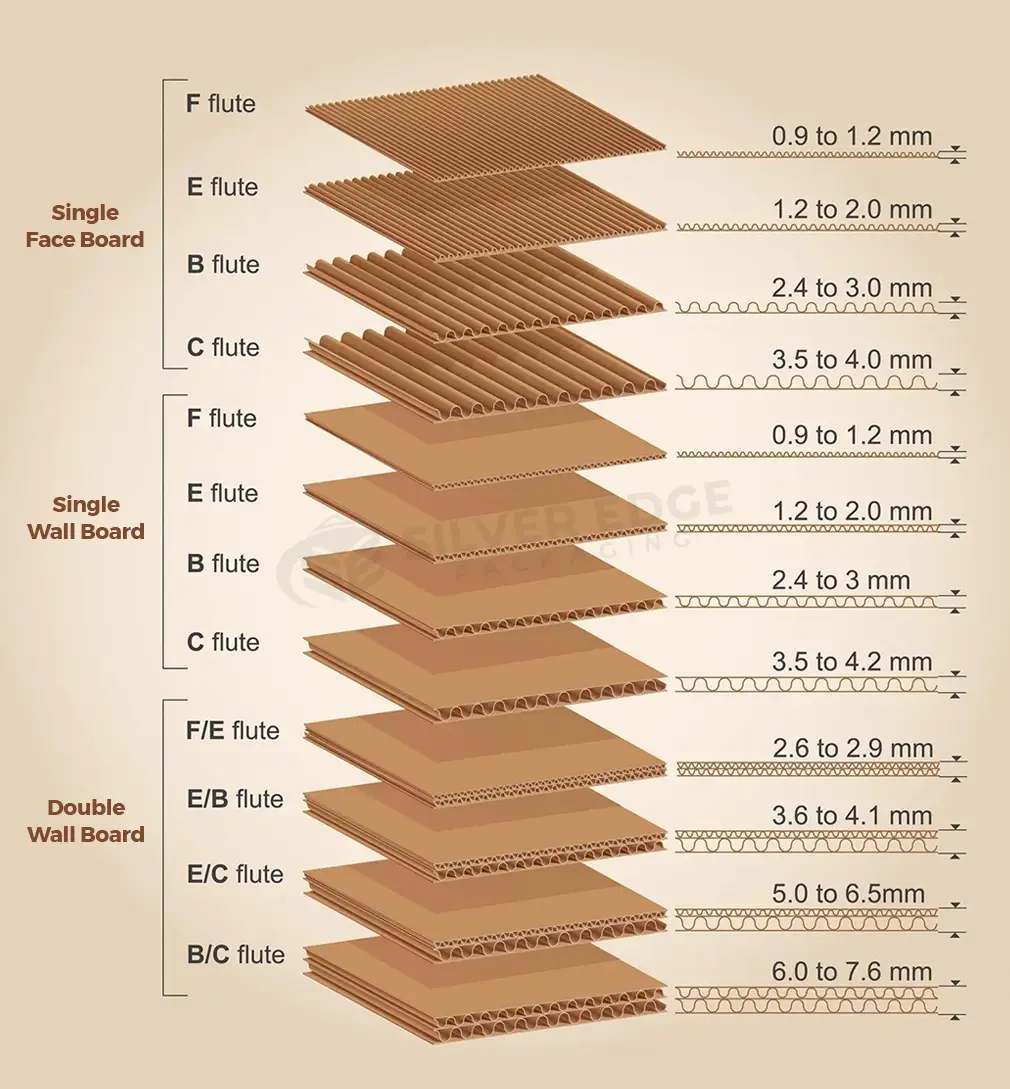

Board Types

Different linear and fluted layers combine to form the board used to manufacture corrugated packaging for various retail items. This guide will help you to know each in depth, which can help you to choose the desired one that suits the protection needs of your delicate items.

Single Face Board

A single face board can consist of either a, b, c, e, or f flute with a single straight layer of kraft stock. Single-face board provides more stability to the packaging and keeps products safe from cracking and other damage. To manufacture single-face board packaging, you can choose any flute of your choice per the protection needs of your products.

Single Wall Board/3-Ply Cardboard

Like the single-face board, the single-wall board can consist of any type of flute corrugated stock. Single-wall board is more durable than single-face cardboard because of its two kraft liners and single flute cardboard layers. It’s also known as 3-ply cardboard.

Double Wall Board/ 5-Ply Cardboard

To manufacture the double wall board, there are two flute layers and 3 liners are used. These materials are more durable than single-wall boards. The double wall corrugated board consists of a combination of various flutes such as B/C, F/E, E/C, and E/B.

For your consistency, we have also provided a visual representation of flute and board types of corrugated cardboard below.

Triple Wall Board/7-Ply Corrugated Cardboard

Triple wall board consists of 7 layers, 3 fluted layers, and four liners. Therefore, it’s also known as 7-ply corrugated cardboard and mostly used to manufacture packaging for bulky electronics, furniture, and other delicate and large items.

Comparison Between Different Types of Corrugated Flutes

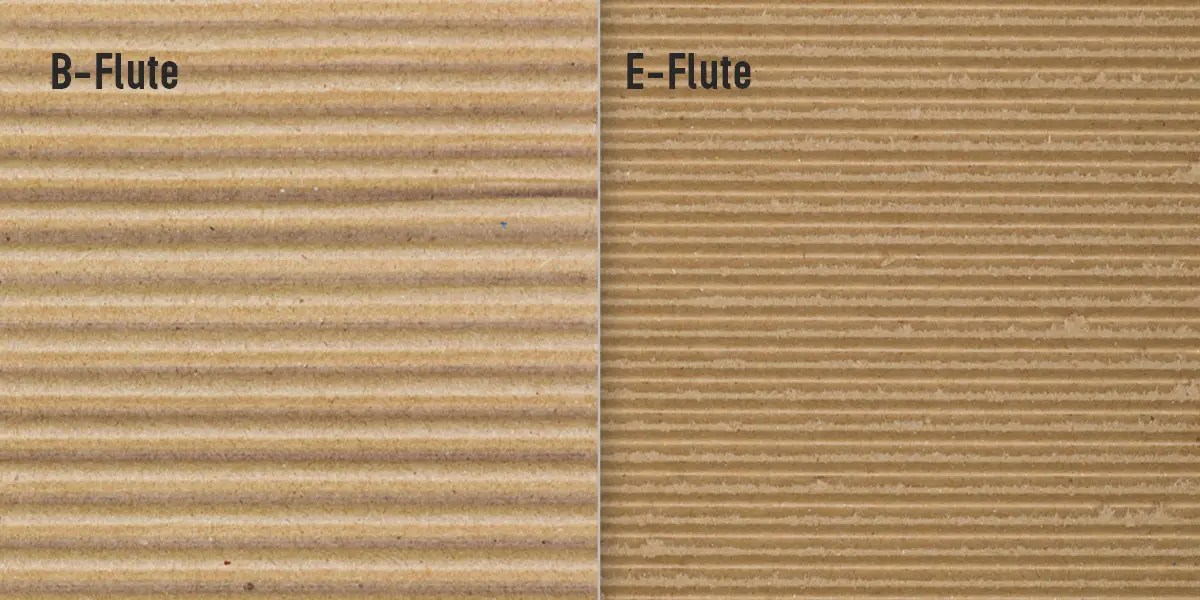

B Flute vs E Flute: Difference

By considering the number of flutes per square meter, we can easily understand the b flute vs e flute. In the E flute corrugated sheets, the number of flutes is more than the B-flute corrugated cardboard. Therefore, the E flute cardboard is thinner than the B flute and best for printing. You can also get an idea about the e flute vs b flute with the help of the given image:

B Flute vs C Flute

In c flute vs b flute, the c flutes have more flutes than the b flutes, considered effective for full color printing and use for the packaging of lightweight items. On the other hand, c flutes provide effective cushioning to delicate items because of their greater thickness. By considering the flutes per square meter, like the b-flute vs c-flute corrugated, you can also learn about the a flute vs b flute.

Corrugated Cardboard Flute Chart

| Flute Type | Flute Per Foot | Thickness in Inches | Thickness in Millimeters |

| A | 33 | 3/16” | 5mm |

| B | 47 | 1/8″ | 3mm |

| C | 38 | 5/32” | 4mm |

| E | 90 | 1/16” | 1.6mm |

| F | 125 | 1/32” | 0.8mm |

After learning about the corrugated flute size chart, we will guide you on their uses in various industries.

Industries That Can Get The Benefits of Corrugated Packaging

Because of their versatile thickness ranges, corrugated boxes are used in various industries to wrap products in a professional way with full protection.

Bakeries

Whether it’s baked items display or takeaway needs, bakery businesses choose corrugated stock to manufacture protective and food-grade custom bakery packaging boxes for their cookies, cakes, donuts, pastries, and other delicious baked items.

Cosmetic Brands

With their premium quality and various thickness ranges, corrugated cardboard materials are used to manufacture a range of protective cosmetic boxes, including luxury perfume boxes that require durability and thickness. These boxes are more affordable than rigid boxes and help brands meet their perfume packaging needs at low rates.

Toys

Toys are made with delicate plastic and other fragile materials. They also consist of various delicate components. Therefore, they require durable packaging to maintain their functionality and protect them from damage. If you offer premium quality action figures, you can also use durable corrugated cardboard sheets to manufacture sturdy action figure packaging.

E-Commerce Brands

E-commerce brands need durable packaging to safely deliver their products. To fulfill this need, packaging companies use various thickness ranges of corrugated flute roller according to the given requirements to manufacture mailer boxes and shipping boxes for them, so that they can safely deliver their products to customers.

Apart from these industries, different types of corrugated flutes are used to manufacture protective packaging for other industries, including electronics, pharmaceutical, automotive, and candle.

Forest Stewardship Council (FSC)

Forest Stewardship Council (FSC) is an international, non-governmental organization that is playing a key role in the management of world forest to maintain healthy forest forever. They provide forest management certification for corporate and individual organizations and for community and family forest. If you are a manufacturer, brand, or retailer you can also get the following certification from Forest Stewardship Council (FSC).

- Chain of Custody Certification

- Project Certification

Apart from this, they also provide facilities to join their organization to play your role in protecting the future of the forest.

Conclusion

The understanding of the corrugated flute profile can help product manufacturers and packaging companies to manufacture protective corrugated cardboard boxes with the desired durability for their products. Whether e-commerce brands or retail brands, corrugated materials are vital for all industries because of their various thicknesses, eco-friendly nature, and excellent durability.

If you need any assistance with the material type or want to order cardboard boxes at affordable rates and with amazing packaging offers, contact Silver Edge Packaging now!

Faqs

What is flute in corrugated box?

The wave-like layer in the corrugated box is called a flute.

Can flutes be combined?

Yes, you can combine different flutes to manufacture thicker stock for protective corrugated packaging for delicate products.

What’s the thinnest flute?

F flute is the thinnest corrugated flute that is used to manufacture packaging for small items.

Does flute direction matter?

Yes, the corrugated flute direction is important for structural integrity and the strength of the packaging boxes.

Which direction are flutes on corrugated?

The direction of the flutes is parallel to the height of the sheet or the box.

How thick is b, c, and e flute corrugated?

B, c, and e flutes have various thicknesses, respectively 3mm, 4mm, and 1.6mm.