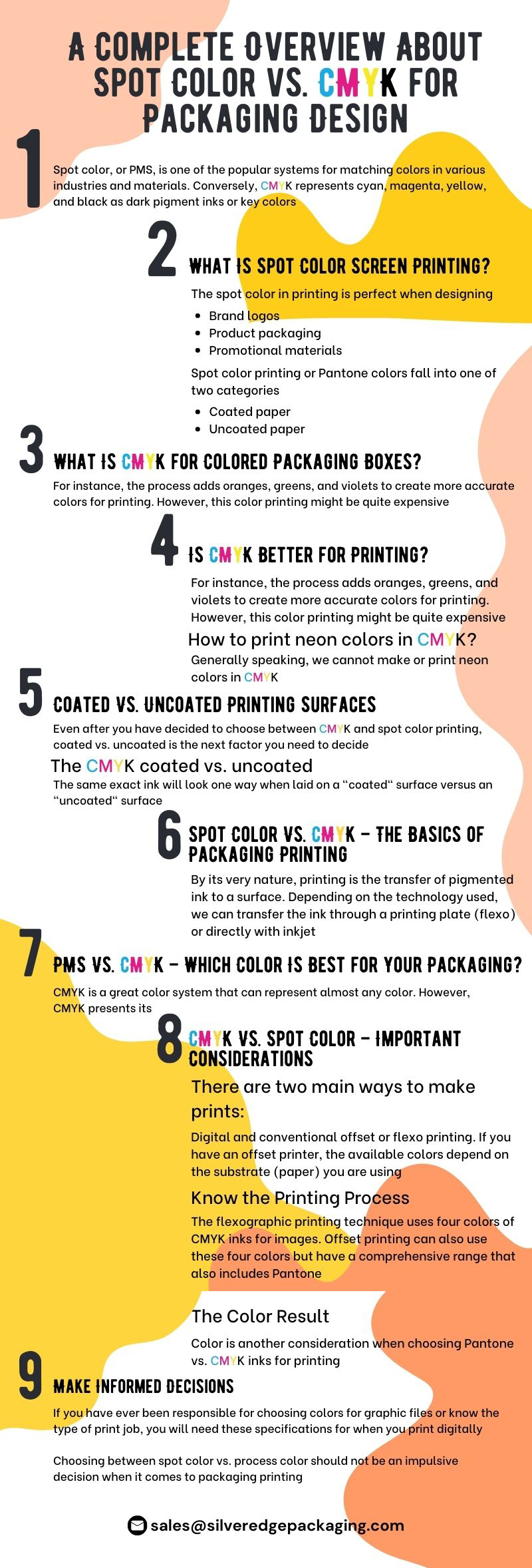

When designing custom packaging, you should be aware of the color models. By understanding the various models, you can then choose the one that fits your appearance needs. Spot color, or PMS, is one of the popular systems for matching colors in various industries and materials. Conversely, CMYK represents cyan, magenta, yellow, and black as dark pigment inks or key colors. While navigating color models can be difficult, an excellent color strategy is essential to successful packaging business. To make things easier, have a look at a complete overview about spot color vs. CMYK for packaging design!

What Is Spot Color Screen Printing?

PMS, famous as Pantone Matching System or Spot Color, is a popular color matching system worldwide. The spot color in printing is perfect when designing:

- Brand logos

- Product packaging

- Promotional materials

In simple words, this system is ideal for everything that needs consistent matches. This applies no matter whether you need to print a standardized, pre-mixed palette of colors in exact hues. Simply put, this is the best color system to ensure a perfect match every time and achieve consistent results.

Spot color printing or Pantone colors fall into one of two categories:

- Coated paper

Coated paper works well for high-quality printing. This paper ensures that your prints are sharp. Additionally, this paper is a favorite one for creating high-quality packaging.

- Uncoated paper

If you’re looking for something old-fashioned, you can use spotcolor on uncoated paper for the kraft board. The uncoated paper absorbs more ink than coated paper. This makes it excellent for a rustic look.

What Is CMYK for Colored Packaging Boxes?

The CMYK system was developed to create photorealistic images. CMYK is a color model that represents the four colors used in the printing process.

Cyan, magenta, yellow, key (black). This is because you start with a white piece of paper and mix layers of primary colors of ink until you get a black or key. In the end, the result will be lighter than any other color on the page. This is also called the process of color subtraction.

When you print something on packaging design and printing, you use thousands of tiny dots to create colors. So, speaking of what are the colored dots on the packaging, they are individual color mergers. Accordingly, they appear as a single color when we view them from a distance.

You can achieve almost any other hue with these four primary colors (CMYK). You can do this easily by mixing them in varying amounts or darkening them by adding black ink.

Is CMYK Better for Printing?

Generally, CMYK color printing is the most common in the industry. Yet, of course, there are other options.

For instance, the process adds oranges, greens, and violets to create more accurate colors for printing. However, this color printing might be quite expensive.

How to print neon colors in CMYK?

Generally speaking, we cannot make or print neon colors in CMYK. This is because of certain factors. First of all, the true neon colors are outside of the range that CMYK can print. To achieve a true neon color with a digital printer, you need to pre-mix the inks. In addition, you need its own special ink cartridge within the printer.

Coated Vs. Uncoated Printing Surfaces

Even after you have decided to choose between CMYK and spot color printing, coated vs. uncoated is the next factor you need to decide. In this context, there is an important distinction between coated and uncoated printing surfaces regarding color.

The CMYK coated vs. uncoated

The same exact ink will look one way when laid on a “coated” surface versus an “uncoated” surface.

When ink is put on a poly mailer, it sits on top of the surface. On the other hand, when you apply that same ink to a Kraft Mailer or an uncoated piece of paper, it gets absorbed into the material. For example, a poly mailer is a coated surface (as are coated papers). Simply put, the coated surface generally has a brighter finish. Meanwhile, the uncoated has a more matte or faded finish.

Spot Color Vs. CMYK – The Basics of Packaging Printing

By its very nature, printing is the transfer of pigmented ink to a surface. Depending on the technology used, we can transfer the ink through a printing plate (flexo) or directly with inkjet (digital).

The print production method you choose for your packaging depends on many factors. The main factor is what kind of graphic you are trying to achieve. In addition, you need to consider how the colors used in that graphic are structured in the file.

The print production method and the composition of colors in the graphic file. This will determine the number of plates required to transfer the design to a box, label, or POS display. Placing your logo in black or two-tone print outside the shipping box is a fairly simple effect. Think simple to complex.

Your graphic needs and your production method will determine whether you use the spot color model or CMYK.

PMS Vs. CMYK – Which Color Is Best for Your Packaging?

CMYK is a great color system that can represent almost any color. However, CMYK presents its own set of challenges.

For instance, it might not be an exact match to some printers hues that use PMS colors. This will eventually give less predictable results than printing from a computer screen to paper.

On the other hand, spot color has a limited number of colors. Well, this can also be a problem if your equipment needs to be able to print a particular shade of blue or red.

In the end, you will find some differences between the process color vs. spot color systems. Yet, it doesn’t matter which one you choose. Why?

Because both work well and will suit your needs.

CMYK Vs. Spot Color – Important Considerations

The first decision to make when printing any material is how it will be printed. There are two main ways to make prints:

Digital and conventional offset or flexo printing. If you have an offset printer, the available colors depend on the substrate (paper) you are using.

Digital printers require software that converts images into code. Codes are transferred to the material in both processes. Whether these codes match CMYK depends on whether you are using inkjet or toner technology. In both cases, the combination of cyan, magenta, and yellow results in a shade of black.

Know the Printing Process

How do you know which printing process you need to print your product packaging?

What if it’s a situation with CMYK or PMS colors, not just black and white ink?

Fortunately, there are some easy ways to find out.

The flexographic printing technique uses four colors of CMYK inks for images. Meanwhile, a digital technique typically uses laser technology only to use cyan, magenta, yellow, and key (black) colors. Offset printing can also use these four colors but have a comprehensive range that also includes Pantone.

The Color Result

Color is another consideration when choosing Pantone vs. CMYK inks for printing. Creating Pantone inks requires more care than CMYK or regular printing. If you plan to print your graphic file in specific PMS colors, you should use those colors from now on. This process is dependent on four different processes: cyan (blue), magenta (pink/purple), yellow, and black.

Make Informed Decisions

Choosing the right PMS shade will be a daunting task. You might have already thought about it. If not, you need to think about it. Then, you need to plan accordingly to make sure everything goes as expected.

If you have ever been responsible for choosing colors for graphic files or know the type of print job, you will need these specifications for when you print digitally. You will need to contact your packaging supplier during the proofing stage on your printer.

Choosing between spot color vs. process color should not be an impulsive decision when it comes to packaging printing.

The two color models offer different benefits depending on your printer type.

For example, if you want your packaging box to have a glossy finish, the colors of your logo are better suited for use as a higher-quality image in this format. On the other hand, inkjet printers require more layers to print evenly on all sides.

Wrapping Up

Indeed, before designing the most suitable color model for your packaging design, you need to know different color models, such as spot colors and CMYK. To get more details, you can simply visit Silver Edge Packaging! Hopefully, the complete overview we revealed in this post will help you out.

FAQs.

Q. What is a spot color screen printing

A spot or PMS color system to ensure a perfect match every time and achieve consistent results.

Q. What is the CMYK color system?

The CMYK system was developed to create photorealistic images.

Q. Which Color is Best for Your Packaging

Both spot color and CMYK will work well and will suit your needs.

Q. How to print neon colors in CMYK?

Generally speaking, we cannot make or print neon colors in CMYK. To achieve a true neon color with a digital printer, you need to pre-mix the inks. In addition, you need a special ink cartridge within the printer.