Packaging is vital to present the products on the shelves, protect them from all sorts of damage, and enhance their perceived value. Whether you are going to start a new packaging company, launch a new product, or want to purchase custom boxes for your products, understanding how much packaging costs is essential. It can help brands to meet their packaging needs within their budget.

The small business package cost depends on various factors, including volume of the packaging, materials, printing, finishing, and other customization options. This article can help you learn the expert guide about the packaging cost to find affordable custom boxes.

Factors Influencing Packaging Costs

Every brand wants to purchase affordable packaging for their products. To help brands reduce the overall cost of the packaging, we provide you with in-depth information about the factors that can influence the packaging cost.

1. Material Used

The materials quality and even a small change in their thickness can affect the cost of the packaging. In this section, we will guide you about the different types of packaging materials to help you choose the one that suits your budget.

- Rigid: Rigid is one of the top-rate premium materials, helping brands to create luxury packaging boxes for their high-end products. They provide an elegant visual appeal to products and also use more expensive materials in the packaging industry. If you have a sound budget limit, you can choose rigid materials. Rigid boxes are the right option for expensive and premium products, such as jewelry, cosmetics, gifts, perfumes, books, and other premium quality retail items.

- Cardboard Corrugated: Like the rigid packaging stock, corrugated cardboard materials are also cost-effective packaging solutions. Because of the demand and supply, transport expenses, and environmental regulations, there is a significant hike in the prices of corrugated cardboard materials. These materials are available in various thicknesses, like the walls or flutes, to meet the different packaging needs of product manufacturers. But these stocks are also best to create more affordable card board box packaging than rigid boxes. You can use these boxes for the shipping of products and for the storage of bulky items. We will discuss how much cardboard boxes cost in the further sections of our blog. So stay tuned with us.

- Cardstock: This is one of the lightweight and premium stocks to manufacture affordable yet luxurious product packaging at an affordable cost. Cardstocks, like SBS, C1S, and C2S, are perfect to create packaging for food items, cosmetics, snacks, personal care products, and other retail items.

- Bux Board: Bux board is one of the low cost packing material for economical packaging. It’s also popular because of its versatile uses, durability, and printing capabilities. The production of this cheapest packing material from the raw material is also relatively inexpensive, helping packaging companies to manufacture packaging at a low cost. Like the other packaging materials, these are also eco-friendly packaging solutions, helping brands to reduce the chances of carbon footprint.

- Plastic (Flexible, Blister): Because of their lightweight and easy manufacturing process, plastic materials are also considered pocket-friendly packaging options. Because of their good barrier properties, these materials are commonly used to manufacturer the primary packaging of the products, including snacks, candies, chocolates, biscuits, toothbrushes, small batteries, and other lightweight retail items. You can manufacture Mylar bags with the help of high-quality PET and BOPET materials.

2. Size and Dimensions

The larger the dimensions and sizes of the packaging, the more material will be used to produce it. Thus, the large-sized boxes are more expensive than the small-sized boxes. Before the customization the accurate die lines are essential to start the production, which can help you to reduce the product cost and the use of raw materials.

For large-sized packaging boxes, you also need large die-cutting and printing tools that can be more expensive as compared to the tools and plates for the small-sized retail packaging.

3. Packaging Type

The cost also depends on the type of packaging. Rigid boxes are more expensive than cardboard boxes. Flexible lightweight pouches are also inexpensive compared to the thick and robust mylar bags. If you have low budget limits, then you should choose the cost-effective alternative for your product packaging. But make sure the packaging ensures the protection and never breaks the reputation of your brand.

4. Design, Printing, and Finishes

- Packaging design cost: Freelance or agency-created packaging design can range from $100 to over $1,000.

- Printing Options: Digital printing is ideal for prototypes and short runs, while offset printing is better for bulk.

- Finishes: Foils, UV coatings, and embossing all add visual appeal but increase cost.

These are the pricing breakdown tactics that can help you meet your packaging needs at a low cost. Let’s learn how much does a custom packaging cost.

Different Types of Packaging And Their Prices

Let’s explore the most commonly used product packaging types and analyze how pricing scales with quantity.

Folding Cartons

Folding cartons are ideal packaging solutions for lightweight products to provide them with an astonishing visual appeal on cash counters or shelves of the stores. The retail display boxes, cosmetics, food packaging, and bakery boxes are commonly the most used folding cartons in the industry. Let’s learn how much they are cost-effective for you.

- Prototypes (1–100 Units): For prototypes, these carton boxes have $0 tooling cost and need $200 – $500 average investment.

- Digital Print (1–100 Units): For the digital print of 1-100 units of custom product packaging, the tooling cost is $0 and needs an investment round about $380 – $480.

- Short Run (500–1,000 Units): For the short run production of the packaging boxes, the tolling cost will be around $250 – $300, and the cost per unit will be $2.30 – $4.40.

- Mid Run (2,500–5,000 Units): Mid run tooling cost of 2500 to 5000 units is from $350 – $500, and cost per unit will be $0.56 – $0.96.

- Mid-Large Run (10,000–25,000 Units): For mid-large run printing and customization of your boxes, you will need to pay $350 – $500 for the tooling cost, and the per unit cost will be lower ($0.28 – $0.49).

- Large Run (50,000–100,000 Units): On bulk or large orders, you can save more money per unit and will pay just $0.09 – $0.17, and the tolling cost will be more ($550 – $950).

According to the given data, the production cost of the small run folding cartons is less than the bulk orders. But Silver Edge Packaging can give you the facility to order your carton boxes and branded packaging for small business at a low cost. We do not charge the tooling cost, and you can also get both small and large orders at highly competitive rates.

Corrugated Boxes

These boxes are mostly used for the shipping of the most delicate and bulky products, including electronics, glass-made products, and acrylic items. These boxes provide excellent cushioning and prevent damage to the product during transit. Here is the information that how much a cardboard box cost.

| Production Type | Tooling Costs | Investment | Cost per Unit | |

| Prototypes (1–100 Units) | $0 | $250 – $1,000 | Not Defined | |

| Digital Print (1–100 Units) | $0 | $350 – $400 | Not Defined | |

| Short Run (500–1,000 Units) | $550 – $2,000 | $2,750 – $6,600 | Not Defined | |

| Mid Run (2,500–5,000 Units) | $550 – $2,000 | Not Defined | $2.75 – $3.30 | |

| Mid-Large Run (10,000–25,000 Units) | $550 – $2,000 | Not Defined | $1.38 – $1.93 | |

| Large Run (50,000–100,000 Units) | $550 – $2,000 | Not Defined | $1.21 – $1.27 | |

If you want to make your own shipping box and want to know how much is a carton cost, the given table can help you get the right idea. These are effective cartoon for packing more expensive and fragile products.

Rigid Boxes or Set-Up Boxes Cost Estimation

These premium yet luxurious rigid boxes are highly popular for packing premium quality products, including jewelry, cosmetics, gift items, and other valuable items. You can also use these boxes for corporate events and the packaging of gifts for events.

| Production Type | Tooling Costs | Investment | Cost per Unit |

| Prototypes (1–100 Units) | $0 – $1,500 | $500 – $5,000 | Not Defined |

| Short Run (500–1,000 Units) | $550 – $1,500 | Not Defined | $5.50 – $12 |

| Mid/Large Run (2,500–100,000 Units) | $800 – $1,200 | Not Defined | $5.50 – $11 |

Rigid boxes not only enhance the perceived value of your brand but also add more value to your products and make a lasting impression on customers. They are also used as custom business packaging because of their premium quality.

Flexible Packaging

Flexible packaging is used as a primary packaging for lightweight products, including snacks, supplements, pharmaceutical items, and other retail items.

| Production Type | Tooling Costs | Investment | Cost per Unit |

| Prototypes (1–10 Units) | $0 | $350 – $550 TOTAL | Not Defined |

| Short Run (5,000 Units) | $600 – $1,800 | Not Defined | $0.83 – $1.10 |

| Mid Run (25,000–100,000 Units) | $600 – $1,800 | Not Defined | $0.25 – $0.59 |

| Large Run (100,000+ Units) | $850 – $2,000 | Not Defined | $0.06 – $0.28 |

Are you looking for economical packaging? Flexible packaging offers the cheapest packing material per unit at high volumes. These are also used for small business packages and for the shipping of products from an e-commerce store’s warehouse.

Blister Packaging

Blister packaging is perfect for packing pharmaceuticals, toys, electronics, and retail items with a plastic front and paperboard backing.

| Production Type | Tooling Costs | Cost per Unit |

| Prototypes (1–10 Units) | $600 | $5 – $10 |

| Short Run (50,000–100,000 Units) | $4,400 – $5,500 | $0.09 – $0.12 |

| Mid / Large Run (100,000–500,000 Units) | $4,400 – $5,500 | $0.05 – $0.07 |

These packaging on products provide full protection and clear visibility of the actual quality. Blister packaging with hang tabs provides the eye-level visual appeal to the products. We hope now you can get an idea about the cost according to the type of packaging for your products.

Packaging Cost Considerations

It’s critical for brands to break down packaging expenses. Whether you are running a small business or a large business, this guide can help you know how to get packaging for a product at a low cost.

Factors to Review:

- Packaging Design Cost

- Tooling/setup charges

- Cost per unit vs. total investment

- Lead times

- Storage and warehousing

- Shipping and logistics

Use a packaging cost calculator to get estimates based on your exact specs, or consult with package manufacturing company for quotes. Silver Edge Packaging is an expert custom box maker all over the world, providing affordable packaging.

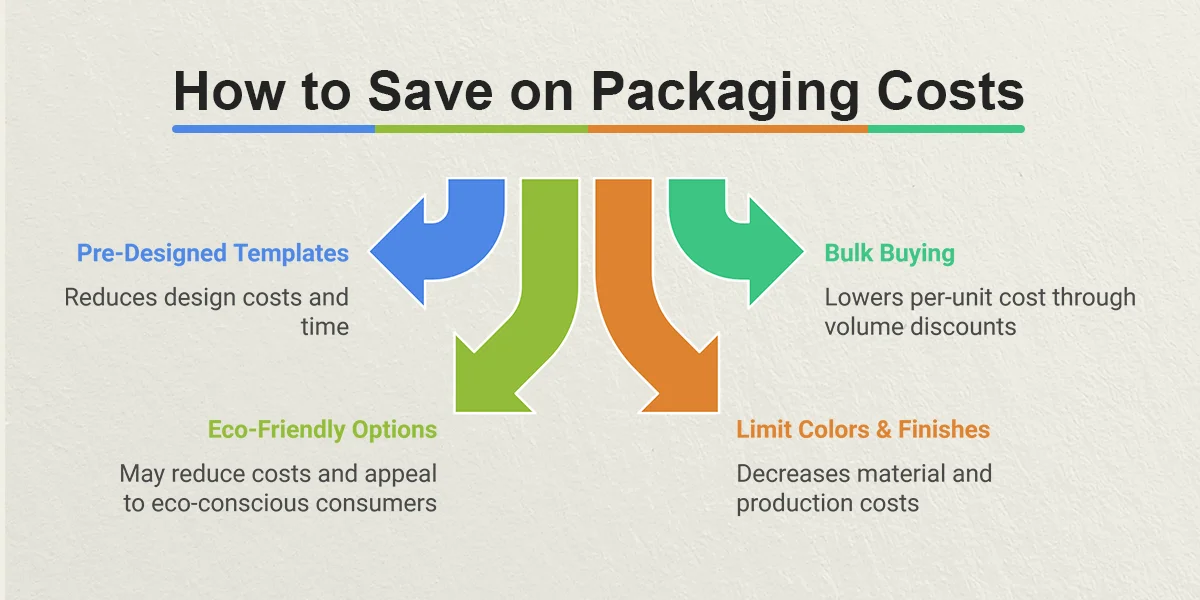

How to Save on Packaging Costs?

Are you looking to reduce your packaging cost? Follow these recommended strategies by our packaging experts:

Choose the Pre-Designed Template

If you want to save the packaging design cost, choose the pre-designed tramples on the website of Silver Edge Packaging.

Buy in Bulk

The bulk order can help you reduce the per-unit cost and get amazing discounts and offers from us.

Eco-Friendly Packaging Options

Eco-friendly and recyclable packaging options can help you recycle the packaging boxes after complete use to create other necessary things. These boxes also reduce the recycling cost by consuming the low energy.

Limit Colors and Finishes

The single-color printing and limited finishes can also help you reduce the printing cost of your packaging boxes.

By following the strategies outlined above, you can reduce the branding package cost.

Final Words

So, how much packaging cost? The cost of the packaging depends on various factors. It can be a few cents per unit on bulk orders and a few dollars on small orders. The premium quality packaging and packaging cartons are more expensive than the single colored product packaging boxes.

If you are looking for how to get packaging for a product on a low budget, Silver Edge Packaging has a solution for your every need. We offer customized product packaging boxes at low rates and with bulk discounts.

FAQs

How much does it cost to ship a package?

The cost of the shipping product depends on the size of the package, its weight, shipping distance, and other factors. So, the cost to ship a package is not defined. Apart from this, the cost of sending package also depends on the shipping company’s rules and regulations about the packaging of products.

Where to buy a box?

You can buy a box or bulk packaging boxes from Silver Edge Packaging at affordable rates and with free shipping.