From the food industry, electronics, pharmaceutical, fashion, and retail to other industries, packaging is used at a vast level to deliver the product with elegance and 100% protection. There are 4 types of paperboard grades to manufacture various product packaging boxes, including CCNB, SBS, FBB, and CUK, which affect the durability and quality of the packaging.

Along with the durability and quality, the cost of the packaging also depends on the varying characteristics of different types of paperboards. Each paperboard has various characteristics to support customization, including printing and finishes.

Let’s clear your concepts about the paperboard types, thickness, uses, and customization options.

What is Paperboard?

Paper-based packaging material is manufactured with the compression of wood pulp fibers to create a thin and durable sheet. These are used for various applications requiring rigidity and foldability, along with packaging. Paper boards have great importance because of their versatile benefits and applications in various industries, including food, fashion, electronics, retail, e-commerce, and printing.

Because of their chemical composition, these materials are recyclable, biodegradable, and eco-friendly, helping brands to reduce the use of plastic to prevent waste and pollution. Paperboard is available in various types, including bleached, unbleached, single-sided coated, or double-sided coated (gloss, matte).

Different Weight Ranges of Paperboards for Paper Packaging

There are different units used to measure the weight or thickness of the paperboards, such as Gram Per Square Meter (GSM), Point System (PT), and Pounds (lbs). In the packaging industry, paperboards between 200-700 GSM are used to manufacture box paper packaging for various products. These different types of papers are used in much-needed thickness to provide the required protection to delicate products during showcase and shipping.

Paperboard Vs Cardboard

Paperboard and cardboard are different types of paper for packaging. These are also used for wrapping gifts and have multiple similar uses. Now, we will guide you about their different characteristics with the help of a comparison table.

| Features | Paperboard | Cardboard |

| Layers | Single Layer | Single and Multiple Layers |

| Durability | Less | More |

| Cost-Effective | More | Less |

| Recyclable | Yes | Yes |

| Uses | Food, Gift Wrapping, Cosmetics, More. | Electronics, Food, Fashion, Beauty, Pharma, and More. |

As compared to the cardboard packaging materials, paperboard is used at a vast level to manufacture food paper packaging. You can choose any paper packaging materials, including brow paper board per the specifications of your products’ packaging needs and budget.

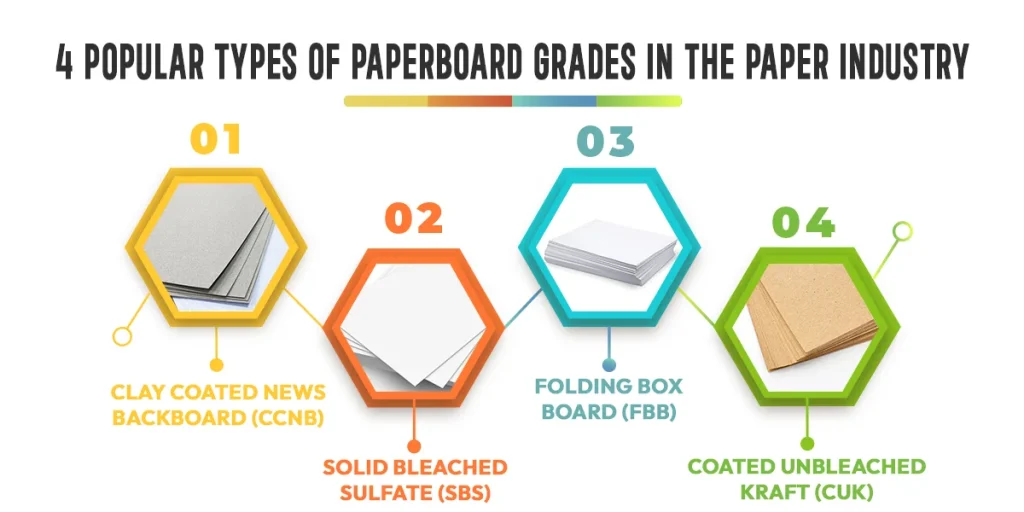

4 Popular Types of Paperboard Grades In the Paper Industry

After learning about the difference between paperboard and cardboard, we will now guide you about the different types of paper grades for packaging. Paperboards are available in various 4 grades, and these paper grades are used according to the packaging needs of brands and products. Each type of paper grade has various uses, benefits, durability, thickness, and chemical composition.

| FEATURES | CCNB | SBS | FBB | CUK |

| RAW MATERIALS | Newsprint, Secondary Paper | Fiber Pulp | Multi-Ply Paper Pulp Materials | Unbleached Wood Pulp |

| DURABILITY | Yes, Less | Yes | Yes, More! | Yes |

| COATING | Single and Double | C1S and C2S | Both | Both |

| COST-EFFECTIVE | Yes, More! | Yes | Yes | Yes |

| RECYCLABLE | Yes, Difficult | Yes | Yes, Consume More Energy | Yes, Effective |

| USES | Food, Laundry, and Other Non-Food Items | Baked Items, Tobacco, Medicines, Electronics, and More. | Cosmetic, Pharma, Food, Stationery, More | Food, Beauty, Candle, and other industries. |

Clay Coated News Backboard (CCNB)

This paperboard is made from a blend of secondary paper, newsprint, and old corrugated packaging boxes. These packaging materials are less effective for printing and affordable as compared to other materials. So, brands use this stock to manufacture folding cartons for food items, laundries, and other non-food items that do not need protection from moisture.

Clay-coated news backboard (CCNB) absorbs more amount of water or moisture, so it’s not effective for the protection of products that can be contaminated with moisture. CCNB paper is one of the most cost-effective paper packaging solutions. With the help of this paperboard for packaging, you can reduce deforestation and pollution chances. Some of the clay-coated materials are difficult to recycle. Brands that are looking for affordable and eco-frienldy packaging solutions should choose CCnB and recycled paperboard grades.

Solid Bleached Sulfate (SBS)

Solid bleached sulfate is the most commonly used paper to manufacture different types of packaging for retail items. This material has excellent durability and strength and is made with chemically pulped fiber. To give the fiber a pure white color, bleach is added. After that, it is thoroughly compressed to manufacture SBS paper. According to Statista’s research, 71% of all SBS stock in the USA comes from North America.

SBS stocks are found in two types, known as:

- C1S (Coated One Side)

- C2S (Coated Two Sides)

These materials are not only effective for printing but are also durable and affordable, which is why they are widely used in product packaging. In printing, you can apply various premium finishes to these paper stocks, such as:

- Embossing

- Debossing

- Hot Foil Stamping

- Spot UV

Because of their premium quality, these packaging materials are highly effective for producing different types of product packaging, such as for baked items, tobacco products, pharmaceuticals, food, stationery, and more. You can also utilize this stock to manufacture cosmetic packaging with premium printing and a durable structure.

SBS (Solid Bleached Sulfate) paperboard, compared to other materials, is not an eco-friendly option. This is because a significant amount of bleaching is used in its production, which releases harmful substances into the environment. Additionally, SBS board paper is typically made from virgin fibers, which contributes to deforestation.

When it comes to cost, SBS stocks are quite expensive compared to other materials. For products that need to stay fresh and be protected from moisture and wet conditions, packaging made from SBS paperboard is not the best choice. It is also not the best option for the protection of heavy-duty products.

Folding Box Board (FBB)

Folding box board is one of the most durable and thickest stocks that is manufactured with various plies of paper packaging materials. Due to their durability and protective nature, these stocks are ideal to provide the desired protection to heavy-duty products during shipping. You can print these packaging materials with the help of offset printing technology with your desired prints. These are effective in creating durable paperboard cartons and custom personalized packaging for various industries, including food, cosmetics, electronics, automotive, and others.

FBB paperboard grade consumes more energy during the recycling process, but they are eco-friendly as compared to SBS paperboard. This is high-quality custom-printed paper and has enough durability to keep items safe from damage.

Coated Unbleached Kraft (CUK) and Natural Kraft (SUS)

After the eco-friendly packaging revolution in the world, the coated unbleached kraft (CUK) and Natural Kraft (SUS) are becoming more popular in the packaging industry. These various types of paper give a natural look to products and ensure sustainability. All kinds of paper are effective paper and packaging solutions for various industries, including food, candle, gift, retail, and others. Food paper packaging and food paper bags predominantly utilize food-grade kraft paper as their primary material.

CUK paperboard is manufacture with unbleached wood pulp, and SUS is manufactured with unbleached wood pulp and recyclable packaging materials. CUK is more effective than SUS when it comes to the recycling of Kraft paper stocks. These stocks are not as highly effective as SBS paper packaging products. Thus, if you want to give a natural brown, black, or white look to your products, you should choose these kraft papers.

Conclusions

Paper grades have great importance in the packaging industry to create custom product packaging for various products. All kinds of packaging materials have their various characteristics and durability to meet the versatile wrapping and packaging needs of individuals and brands. We hope with the help of this article, you can easily and confidently choose the right type of paperboard to meet the packaging needs of your products.

FAQs

Where can you buy packing paper?

You can buy your desired packaging paper and packaging with custom printing from Silver Edge Packaging at affordable rates.

How many types of paper are there?

There are four types of papers there, including CCNB, SBS, FBB, and CUK.