In the market, you have noticed lots of product packaging boxes. Have you ever thought about how the graphics, colors, and typography get printed on them? Whatever the packaging of the product, including retail product boxes and gift boxes, the printing in a professional way makes them more appealing and gives them a sophisticated visual appeal. Printing elements, such as the company name, color, and specialized design on the branded boxes, can help the brand depict its brand image.

For the packaging printing, there are two common ways, such as litho printing and flex printing, which are gaining more popularity. In this blog, we as packaging experts will help you to learn about litho vs flexo printing, how both work, and which one of more suitable for the printing of your custom boxes.

Why Printing Choice Matters in Packaging

In a competitive market, it’s vital for brands to get personalized packaging solutions for their products. In this case, printing in a professional way can help brands to stand out their products among the mess and guide people to what’s inside the box. An elegantly printed boxes not only differentiate the brand but also attracts customers and provides a premium visual aesthetic to products. There are different types of printing methods used to print these boxes according to the needs of brands. Thus, choosing the right printing technique is vital for brands to get the desired printing effects. These options or printing methods work in a different way for various materials, designs, and budgets.

Let’s learn about the detail guide of litho & flexo before going deeper.

What is Flexo Printing?

Flexo printing, also known as flexographic printing. In this process, the printing ink is transferred onto the required materials with the help of flexible rubber or plastic plates. These plates are wrapped around the flexographic machines’ rotating cylinders to provide a smooth printing experience. Do you want to know how a flexo printing machine operates? If so, here’s how flexo machine printing works:

Working Method

In this process, the raised image or text is on the plates wrapped around the rotating cylinders. So, the inks are applied to these plates to get coveted and precise printing results on printing elements. In this printing process, the plates roll over the materials, including cardboard, kraft, cardstock, and other printing materials, to transfer the inks according to the color schemes.

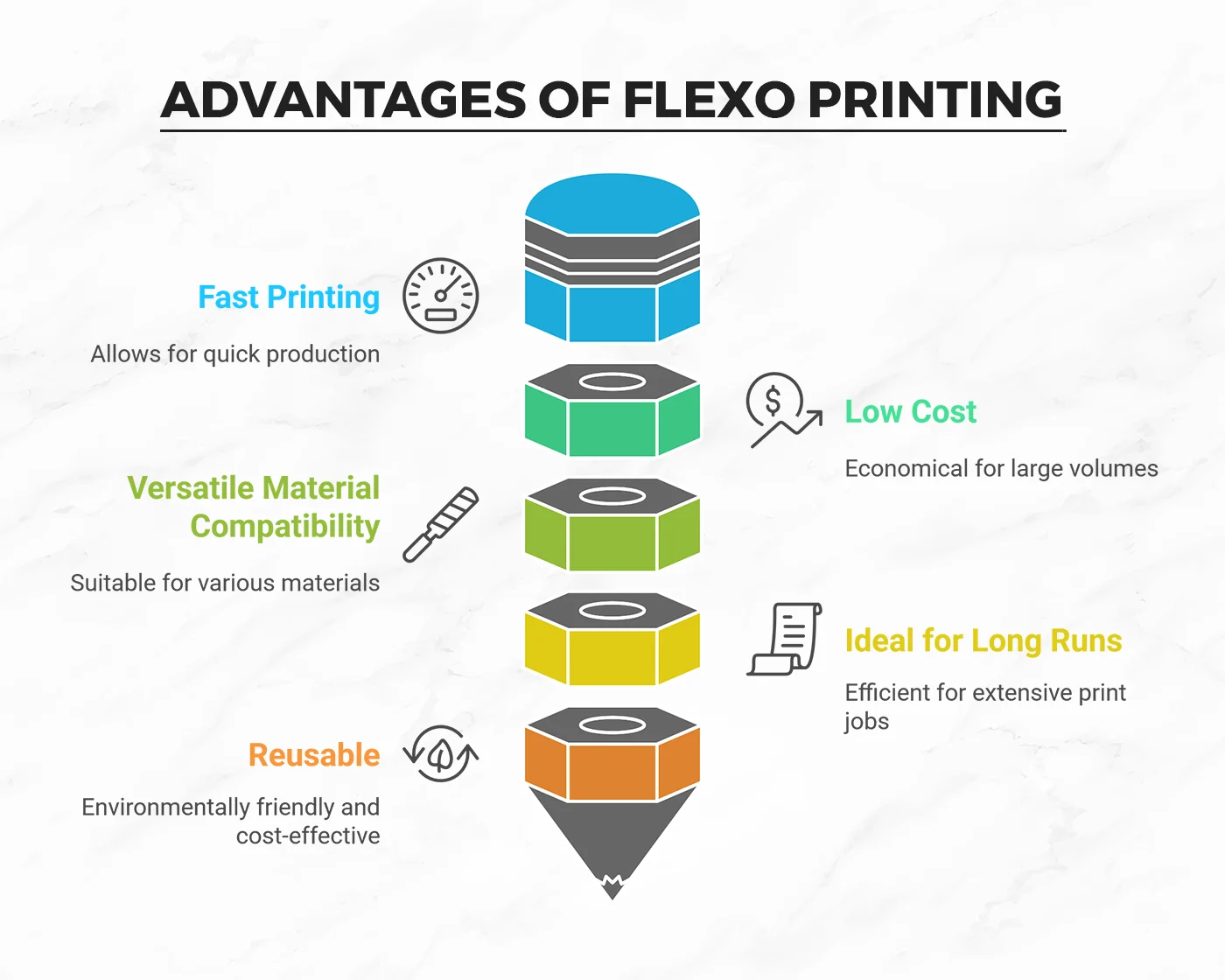

Advantages of Flexo Printing

Flexography printing is highly effective in the printing industry because of its range of benefits.

- Fast Printing: Flexo machines print faster, whether for a small order or a large order. But it’s more effective for the large printing runs.

- Low Cost: With its great speed, it has a cost-effective approach as compared to litho printing. It provides clearer and precise printing results of the simple box designs.

- Works on Many Materials: Whether the corrugated stock or kraft materials, flexo printing options work well with these uneven surfaces to provide clear and appealing visuals.

- Right for Long Runs: If you want to save the printing cost, flexographic painters are useful to print your long-run orders of custom product packaging boxes in a short time and low budget.

- Reusable: Flexographic printers’ plates are reusable. You can clean them after printing to make them useful for a repeat job. They can perform millions of impressions before replacement.

These printings are not only cost-effective options but also sustainable options for printers.

Limitations of Flexo Printing

Flexographic printing is not suitable for short printing runs because of its high initial cost of printing plates. This printing method does not show the precise printing details like the digital printing and offset printing methods. Plus, it’s not right to print the photo-like images with various color schemes. It does not produce the sharp color printing on the surface of rough materials.

What is Litho Printing?

Litho printing is also called lithographic printing, or also known as litho print. In this printing method, high-quality graphics, images, and typography are printed on the surface of any paper material. After the completion of printing, the printed materials are glued to the surface of any rigid box. This printing technique is more complex as compared to flexographic printing, providing.

Litho printing, also called lithographic printing or litho print, is a method that prints high-quality images on paper, which is then glued to the box. The process is more complex but gives excellent results.

How it Works

- Plate making: An image for printing is etched onto a flat plate, which is originally known as a limestone or aluminum plate.

- Inking: After the plate making, the water is applied to the non-image area of the plate. This area will absorb the water. After that, the ink rolled on the plate, and it stuck to only the glossy area of the plate. The water area repels the inks.

- Transfer to blanket: The inked image is transferred from the plate to a rubber blanket.

- Transfer to Printing Material: The blanket then transfers the image onto paper or another printing material.

- Final print: An impression cylinder applies pressure, pressing the image onto the surface for sharp and high-quality printing results for the premium product packaging.

Advantages of Litho Printing

Lithography printing provides multiple benefits, including:

- High-Quality Printing Results: If you want to get high-resolution printing for your product packaging, litho printing is one of the best printing options. It’s also useful for small fonts and sharp color printing as compared to flexographic printing.

- Cost-Effective for Large Printing Runs: The cost per unit for large printing runs is lower than other printing methods. So, it’s highly cost-effective for printing bulk custom boxes.

- Multipurpose: You can use this printing technique for the printing of various marketing elements, such as flyers, leaflets, brochures, and packaging boxes.

- Great for Marketing: Makes products look premium with the luxury printing of graphics and logo.

- Wide Color Range: Litho is useful for printing various sharp colors on various packaging materials for the elegant visual appeal of packaging or any marketing elements.

If you want premium quality custom printing boxes with logo in a short time and within your budget, you can confidently choose litho printing. It can help you add more value to your brand and products. You can use this printing method for packaging of your premium products, such as jewelry, cosmetics, gifts, books, subscription, PR packages, and other high-value retail items.

Limitations of Litho Printing

Litho printing is more expensive than the flexographic printing options due to its setup and raw materials. It takes more time for the printing of long run, taking more time to prepare. This is not an ideal printing option for rough surfaces, but for smooth and precise printing results.

Litho vs Flexo: Key Differences

Let’s look at the difference between flexo and litho printing in a few key areas.

- Print Quality

Litho printing is better for fine details and high-quality images.

Flexo printing is good for basic designs, text, and logos.

- Cost Efficiency

Flexo is more cost-effective for large quantities.

Litho is more expensive due to setup and materials.

- Speed & Scalability

Flexo machines can print very quickly and handle big orders.

Litho takes longer to set up and is better for smaller or premium runs.

- Material Compatibility

Flexo works well on many materials, including corrugated cardboard.

Litho works best on smooth surfaces and laminated boxes.

- Plate Durability

Flexographic plates can be reused many times, making flexo more sustainable.

Lithography plates are reusable, too, but need more care.

Comparison Table: Litho vs Flexo

| Feature | Flexo Printing | Litho Printing |

| Print Quality | Basic to moderate | High detail and sharpness |

| Cost | Low | High |

| Setup Time | Quick | Longer |

| Best for | Large runs, shipping boxes | Premium packaging, branding |

| Material Types | Corrugated, uneven surfaces | Smooth, laminated surfaces |

| Plate Reusability | High | Medium to High |

| Speed | Very fast | Slower |

Flexo vs Litho vs Offset Printing

Now, let’s talk about offset printing and how it compares.

Flexo vs Offset Printing

- Flexo printing vs offset printing: Flexo is faster and cheaper for packaging. Offset is slower but has great quality.

- Flexography vs offset printing: Flexo is better for boxes; offset is used more for books, newspapers, and flat prints.

Litho vs Offset Printing

- Lithography vs offset: Litho is a type of offset printing. Both give high-quality prints, but offset is often used for paper products, while litho flexo is used for packaging.

Which Method to Choose for Box Printing?

When Flexo is Better

- In case you need a large number of boxes in a short time and at affordable rates.

- Idea, if you want to save money on your packaging printing for your other business tasks.

- It is used for rough materials, such as kraft and corrugated, to create customized shipping boxes.

- When you need fast printing for bulk printing runs.

When Litho is Better

- Best to produce custom packaging boxes with premium and high-quality printing results.

- When your box design has detailed images, graphics, and many colors for printing.

- If you want to make a lasting impression on your customers, litho is the right printing option.

- Litho printing is ideal for printing premium product packaging, such as gift boxes, jewelry boxes, and rigid boxes.

Conclusion

When it comes to litho vs flexo printing, the best choice depends on your printing needs. If you’re printing simple designs on bulk boxes, flexo printing is the right option in printing. It’s fast, cheap, and works well on corrugated cardboard and other rough materials. But if you want premium quality custom printed boxes that really wow your customers with their printing results, you should go with litho printing. It is worth the cost by providing fancy designs, sharp images, and vivid color printing on your paper materials.

Whether it’s flexo vs litho, litho printing vs flexo, or even flexo vs offset printing, now you know which is best to meet your printing needs. Get the help of this blog to choose the right printing method for your packaging needs! If you are looking for the printing and packaging company that can meet your needs professionally and without breaking the bank, Silver Edge Packaging is a one-stop shop.

FAQs

What is the difference between litho and flexo printing?

The difference between flexo and litho printing is one the base of their quality and cost. Flexo is cheaper and faster but has lower quality. On the other hand, litho is high-quality but more expensive.

Is flexo cheaper than litho?

Yes, flexo printing is cheaper than litho printing because it is used for a few packaging materials. Apart from this, this printing method has a quicker setup as compared to litho printing.

Why can lithography plates be reused?

Lithography plates can be reused because they are made from metal and can be cleaned and stored carefully for again use, helping brands to save the printing costs.

Which printing method is better for corrugated boxes?

Flexo printing is better for corrugated boxes because it works well on rough surfaces and is more cost-effective for large printing runs.